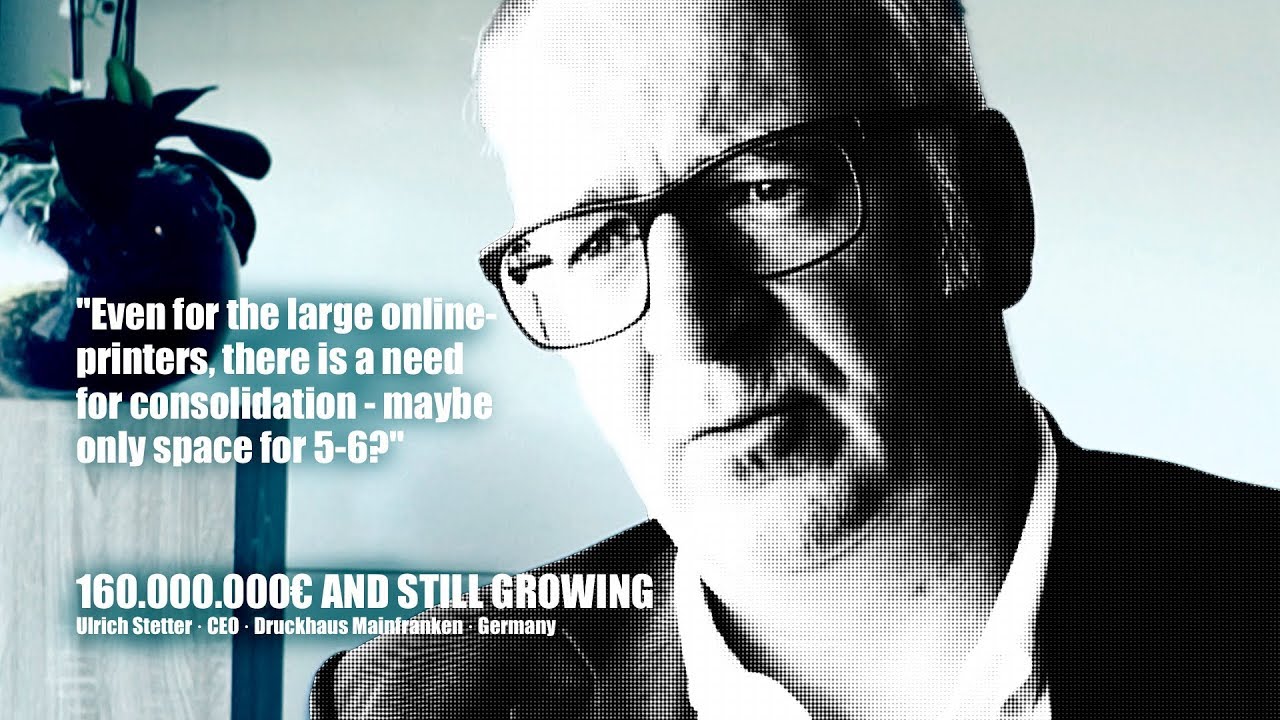

160.000.000€ and still growing · Ulrich Stetter · CEO · Druckhaus Mainfranken · Germany

One of Europe’s largest printing companies is Druckhaus Mainfranken. They see themselves as an Industrial printer primarily delivering offset print to their sister company Flyeralarm.

Mainfranken is managed by CEO Ulrich Stetter, who gave a presentation about their use of enhancement like digital UV/foil at the recent Inkjet Update conference. Excellent presentation, but even greater that CEO Ulrich Stetter took the time afterward took time talk to INKISH.TV.

Enjoy this very interesting interview.

The printing group is Druckhaus Mainfranken. I’m the CEO of the printing group and we have additional companies. We have the Schleunungdruck, that’s the traditional, commercial printer near Wurzburg. We have the Druckerei Thieme, eastern Germany, specialized on very high quality products. And we have the Druckerei Weng that is specialized on gluing, putting things, glue on printed products. So, at the moment, we have a complete group of 1,500 employees together.

I have studied in Stuttgart, in the University of Printing, Economics of Printing. I finished, I think around 88, 89, then working in different companies of the printing industry, newspaper, rep or business. And then, I change over to the Schleunung Druckhaus Mainfranken group, end of 2006. That was a complete new experience because until that, all the businesses are going down, we have reduced employees, things like that, not always funny, and therefore, from that point, we are growing. We are building new plants and developing the business, the printing industry in other direction.

I’m very optimistic because it’s only the question that you are talking to your customer, if you’re online or not, if you’re a commercial printer, if you’re online printer, and you just have to look where the needs of the customers are. We are very successful, even in the commercial part, because we are developing solutions for large customers for example, solutions for used instructions, one example. And that’s not more a question of printing and color, bringing color and ink on the paper. That’s a big question of logistics, to bring in the right use instruction, the right number, the right language, at the right moment to the packaging line of our customer.

Therefore, for me, it’s not a question, success of the printing industry or do we lose the printing industry. I think print matters and it’s only talking about the needs of the customer.

The success of Flyeralarm is that Mr. Fisher, he found and said, “What is the problem buying printed products?” You have to wait one week to get an offer, you get an offer which is very expensive and you cannot understand everything what’s inside this offer. They are talking about PDF, PSO, and things like that, and you as a normal customer that I just want to have 500 greeting cards or 500 magazines, that’s too much for you.

Therefore, he said, “Okay, what does the customer want?” He wants fast delivery. That’s the Amazon effect, what we said. He want to have fair prices, lower prices, and very fixed prices, so, he can see immediately when he’s looking on the product. He can see what are the cost for this product. I think that’s question what every printer should think about. That’s not a question of if online or not.

Yes, yes, they are stop developing, and if you said we talk before about economics, they are not looking on some effects, and they are not calculating. They’re not doing a real calculation and therefore, they’re walking in through the customer’s door, and said, “Okay, we can do. It will be cheaper. We can make very low prices.” They are not talk about the quality, not about the services, the most important part, not the services. Therefore, they should not wonder about what’s happening then.

I’m not sure but I think in one part, yes, and they have been fixed too long on their presses. So, sometimes, you can see people are buying presses and said, “Why have you bought only six color of wood varnishing?” “My colleague has a five color wood varnishing, so, I have to buy a six color wood varnishing.”

That’s for a very long time. When there is money in the industry, in the good years of the industry maybe, and therefore, they not did too many calculations. They just think, “Okay, let’s buy the next press and the next press must be bigger one.” And nobody is thinking about scaling down and reduce, go from four presses to three presses, and being more efficient.

We have started. When we have started with this industrial printing, how we call it, when we started 2006, 2007, we had it for make ready in the large format of set press, four colors. We have a make ready time of 17 minutes. We are now in the large format, we are in about four minutes or less. In the middle format, we’re in format, 106 cm. We do a complete make ready on the eight color in two minutes or less. You have to think about the processes, you have to think about every single step, how the printer does move to put the sheets out, to control it. When did he control? Could you wash the blankets during that time?

You have to think about every single second, and then you can bring this time down. I’m sure that we’re not at the end of these possibilities, and talking about printing of set presses, digital presses, I think we are there at maybe 90% of the efficiency we can get. Going to the post press department, I think we are at 65%. It’s a long, long way to go and we said always, in the morning, if we make up and have some ideas, how we can make it to improve it, then it will be a good day.

They said, “Okay, that has been a very expensive press. I don’t want to invest in the training for the operators. I’m buying the press for €4 million but I don’t want to take €100,000 or even €50,000 to make a real, very good training for the operators, how to use this press.” And after some months, they are wondering and said, “They are using the press like before because they have been trained as presses running with 12,000.” They don’t ask the press operator, don’t ask and say, “The new press should go 14, 15, 18,000,” and that is one question and one problem.

Yes. We did a lot of training and we always be in the change. Nobody in the company said, “Oh, that’s how we make it here. We have made it for the last 20 years and that’s working,” therefore, that’s interesting because … and even talk to these employers. We said if we’re buying a press, we are not want to a buy a press, we want to buy productivity. And then, we go in details and said, “Okay …” Spare parts for example, what is the average workflow of a problem on the press? The printer is looking for maybe one hour, said, “Something is not going like it has to be.” After one, two hours of looking, of asking, he’s calling the service. The service, maybe in our case, they are mostly in-house but they are coming maybe after an hour, then they’re looking inside the press.

If it’s not such a big problem, they said, “Okay, that’s the part which is not working. I need this part.” Then, you wait for eight hours to get this part from the plant, from the manufacturer. And then, they put it in, half an hour maybe, then test it, look if the press is now working, and then go back in production.

So, you have a complete time which is not productivity of about 10 hours, but seeing that something is wrong and repairing it is about half an hour or maybe one hour. So, what we have done, we have analyzed all the spare parts, put it in-house, and then we reduced this time from 10 hours to one and a half hour. And we tell the press operator, “If something is wrong, you have exactly 10 minutes to stop and say, okay, something is wrong. You don’t have to look and to ask, and to try for two hours. After 10 minutes, call the service and say we have some problem with this press.”

The management is the part. Sometimes, we are looking for new machinery, we have an idea. We’re rethinking or we’re developing complete workflows. So, we come from a product and say, “We want to offer hot foiled greeting cards, 100 pieces.” And then, we develop the workflow completely, and said, “How can we produce this very efficient within one day?” And then, we have to go to the supplier and the supplier said, “No, no. That’s not possible. We cannot do this.” And so, first step, sometimes you have to hold the supplier on the hand and said, “Come on with me.” We walk the line, go along and we will bring it into production.

I think it’s the DNA of our company and of our group that we said, “Okay, we always try.” We always want to be better every day. It’s not only that we’re talking about that, that we said a lot but the people working there, it’s a kind of family and we want to be on top of this business, therefore, we want to make it like this.

We think the online printing market, how we define this business to business mainly, we see it’s half of the market is developed, about, in Europe, and it’s a long way to go. Maybe it’s five years or so, they are growing now, they are doing a good job.

So, it’s interesting and we see a huge possibilities for this market, for the next future. But as I said in my presentation before, it will be not the case that we are covering the complete print market. That makes no sense because a lot of very interesting and huge products like the huge catalogs or newspapers, or very special things like money, printing bank notes. So, these products need a lot of know how and therefore, we see we can cover the small quantities and the special niches of the market. In the past, we said, “Oh, we are printing all the things nobody wants to print.”

For our business, for the online printing market, industrial printing, we said size is very, very important because we can offering some services, we can start with an Scodix for example. Covering one shift and then, grow, and if the competitor has only half of the volume, he cannot start. If we start with a half shift, we’re always six hours a day, and then go, growing year by year, it’s efficient. If you have half of this or one third, it’s not efficient, we cannot start that business. Therefore, focused on the online printing business, we said, “It’s very, very important that we have a kind of size.”

And what we are doing with the different plants is that the plants are not focused on regional areas or countries, they’re focused on products because we have such a huge number of products and that means that one manager of one plant, if he should produce everything, he cannot. And that means we’re focused in one plant who’s producing four, five, six main product lines, and this plant can focus on that technology. That’s very interesting topic because if everybody should do everything, that’s not working. And that’s a big benefit to some of our competitors, that they want to do regionally, they print in Italy, they print in Germany, everything same, and that’s not working so nicely.

For the traditional printing industry, I can see that there are very interesting print ships up to 10 or 15 employees because they’re very flexible. It’s very difficult between 15 and 50 because you have some regulations, you have some laws, you have some rules and some questions of your customer, of the market. That’s difficult, that’s really difficult because as the manager in this size of company, the whole day, you have to fill in some government forms and things like that.

Up from 50 or 70, from my point of view, commercial printing, ideal 150, 200 employees, that’s a interesting part. Looking on the statistics of the German Printing Industry Association, you can see that they are very effective.

The bigger ones, I think that there are only less than 10 companies with more than 1,000 employees. We had some bigger problems in the rep heat set printing of business, some real big problems. And then now, there are lot of some book printing companies, some specialist, very interesting, very profitable. That’s interesting too.

In the online printing business, I think at the end, we will see five, six, seven companies. It is our top five now in Germany, they are covering, mainly, the European market, and these are these five. It will be very difficult to go within this, to be part of these of five. And the other ones, yes, we see that the number of companies will be reduced and there, I think we will go down to maybe 4,000, 5,000 companies, yeah.