Martin Leitner · Director Product Management · Labels & Flexible · Durst · LabelExpo Barcelona 2025

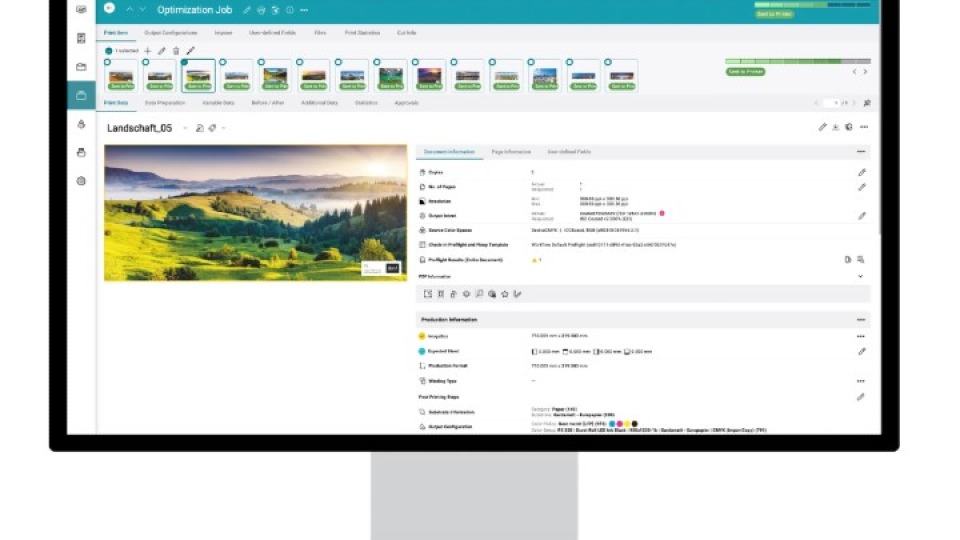

Morten from Inkish interviews Martin from Durst at LabelExpo 2025 in Barcelona. Martin explains that Durst’s mission is to lead the label industry’s transition from conventional to digital production, constantly adding new features and technologies. He says digital inkjet printing is now fully industrial—reliable, simple to operate, and no longer in its infancy—and that the industry’s focus is shifting toward people, automation, and software to enable more efficient production, potentially even lights-out manufacturing in the future.

He notes that while hybrid presses remain important in some regions, especially in the US and parts of Europe, standalone digital presses are still the core of Durst’s business because of their flexibility, shorter web paths, and ease of operation. Martin also points to growing demand for personalization and especially variable data printing, with customers now regularly producing up to 100,000 linear meters of variable jobs per week, which requires a strong data infrastructure and automation to feed data to the press efficiently.

Martin introduces Durst’s new Tau 340 G3 platform, which builds on their previous models but brings a range of improvements. It maintains 1200×1200 dpi resolution and speeds of 80–100 meters per minute across 340, 420, or 510 mm widths, offering more flexibility and productivity. The G3 features a redesigned operator area, new systems to protect printheads from poor-quality or wavy materials, automatic registration, new backend software, improved electronics and temperature control, and many other visible and hidden enhancements that reduce waste, speed up setup, and make operation easier. He says the G3 will succeed the Tau 340 RSCI platform while the current RCE model remains available.

Martin concludes that the G3 is designed to be highly reliable, easy for operators to run, and backed by Durst’s in-house expertise in chemistry, mechanics, and software, along with knowledge drawn from other industries like graphics, textile, and ceramics—making it a strong step forward in digitalizing the label industry.