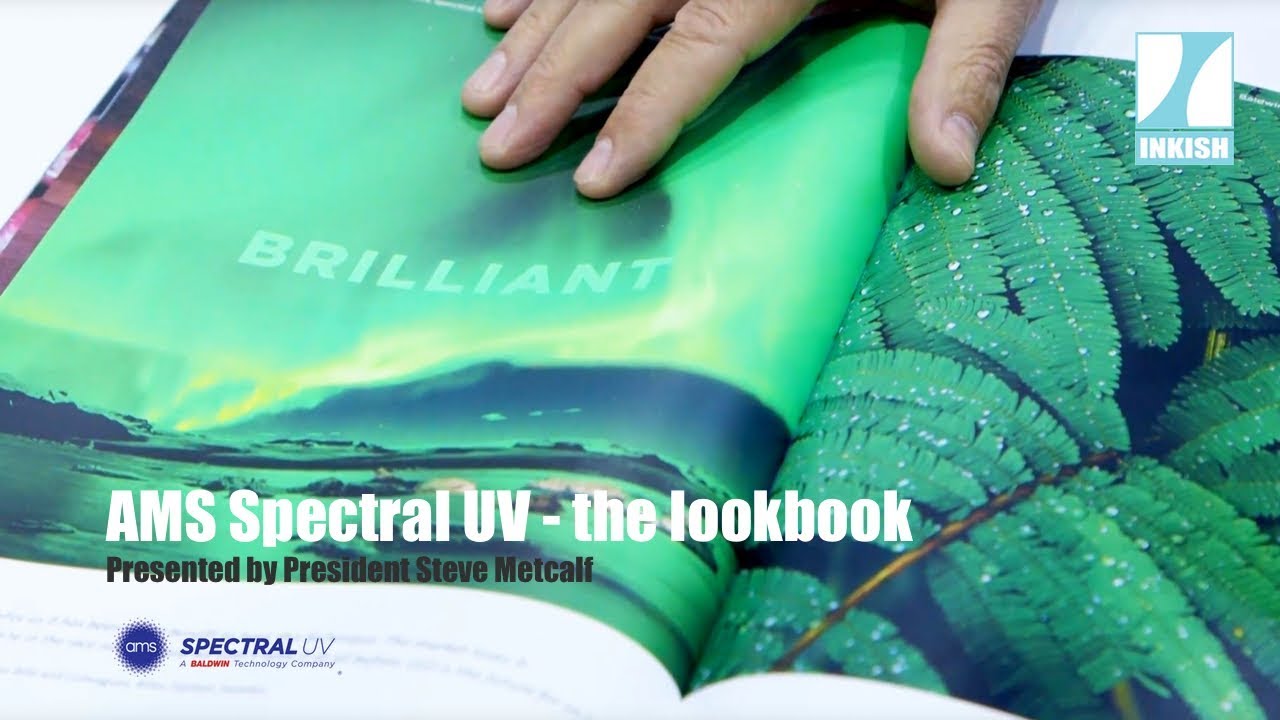

INKISH.TV Proudly presents: The AMS Spectral UV Lookbook

Substrates and effects are quite difficult to show on video and though we rarely do this on INKISH.TV we really liked the new lookbook V2 from AMS Spectral UV. President Steve Metcalf presented the lookbook at Print17 and we bring here a more or less un-edited version of his presentation.

What is worth thinking of is the fact that the entire book is done on a 6-color B1 KBA printing machine with one LED UV lamp. No effects have been added in screen afterward – so what you see is what you get.

The lookbook shows the potential of UV-print and since both inks and investment in UV is dropping these years and you even can buy equipment from all the major vendors with pre-installed UV – AMS Spectral UV – now a part of Baldwin – has really pushed their way into printing companies worldwide.

As Steve Metcalf also explains in the episode – the ink densities can be dramatically increased and since curing is instant you can even print with high densities on un-coated substrates, on plastics and this, of course, opens up for a lot of new applications for a printer.

A while ago we also spoke to Marc De Jong from Deltabach in Holland about his investment in LED-UV and as he explained he was having his company in a relatively small place, the instant drying of the printed paper gave him extra space since he didn’t have to stock printed paper before binding.

With Baldwin’s investment in AMS Spectral UV, it is, of course, interesting to see whether LED-UV will lead over H-UV. Baldwin delivers both technologies.

0:09 We’re very proud of this. This is really the latest manifestation of the state of the art, what can be achieved with an LED press, and whether it’s a new machine with LED, whether it’s a 10, 15-year old machine with LED, you can start to work on these kinds of projects. And, what this look book does is really show not only the vibrancy of the ink on every different kind of substrate we can imagine, but also special effects that are now achievable with the coatings and the varnishes that are also designed for LED. And, it’s a single pass, one LED lamp doing the whole work, and you’re running at full production speeds without a single concern for marking or scratching or powder or other things that have traditionally been in the process. You can pile them high and go straight into your bindery to your customer. And so, this this look book really is what’s driving a lot of the interest in LED, and just the sheer amount of attention and incredible effects that we can do this. And, we love doing this kind of work.

1:05 So, to talk a little bit more about the look book, and this is our LED look book version 2.0. So, we found the first version was last year at Drupa, and was really one of the most amazing pieces that was at Drupa. I think, and I’m saying it from a point of view that we’re very proud of what we’ve done, but really to showcase the state of what’s possible with LED-UV technology, and combine with the power level generation that we bring to the print market. And so, we were so excited to work on this new version. What you see in this booklet is all the effects that you can take advantage of now, the state of the art with LED-UV printing on an offset machine. And, in this particular case, this was a six-color machine with a coater, an Anilox coater, and through the combination of the ink and the coating, we can produce this spot effect or drip-off. Some people call it the strikethrough effect. And, that’s one of the most amazing things because it allows sort of a feeling to come out on the sheets in addition to the brilliance of the ink on multiple substrates.

2:06 You can also begin to see how we’re taken advantage of in register spot curing at a very, very low cost. It’s rivaling some of the output that you see on some of these advanced digital enhancement machines on the market, such as a Skodex or an MGI. But, you’re doing this on an offset press, so the ability to do in register spot on a variety of different substrate types. We’re also showing the range of materials, so as you go through this look book, you see some of the normal papers, silk coated papers, you see the nature papers or the uncoated offset papers, and just the density and the vibrancy that we can pull out of these images. You see, as we move into the realm of plastics, so many printers are dealing with plastics in one form or another, whether it’s a synthetic material, synthetic paper, like a Yupo, or whether it’s the traditional plastics that you find in films of various sort of see-through type applications. There’s also been a lot of demand for papers that have a feeling like canvas, or just a very rich feel that are coming out of the paper mills, and for art books or other high-value materials. Several of our LED printers are the suppliers to the most famous museums in the world because of the quality and the brilliance of the LED.

3:18 So, this has shown again through the type of paper. Again, bringing back spot effects that can really enhance just subtle, subtle areas of an image. In this case, on the Porsche, you see just on the grille and on the name tags and the plates, you see just a slight subtle variation of the light and the effect.

3:37 Which looks like something that is pumping out of it.

3:40 Yes. And, you see watermarking ability. So, there’s an ability for whether it’s a security product or something, you can bring in this technology easily. The availability of more advanced inks. So, several years ago, it was hard to find inks that were true Pantone across all the ranges, and now we have neon inks, such as this green available, that really allows another level of effect. Here, you see an example of something in a rain forest, but you see each individual droplet has a spot effect to it, bringing that to life in a way that has sort of an emotional effect, in addition to a plain effect.

4:17 I was about to pick up a napkin to wipe it off because I thought it was wet, but that was not the case.

4:20 Yes, exactly. And, that’s the idea. And, it doesn’t have to be screened on in an offline process. This is all done in line and single-pass with one LED. You’re just the security of cure. One of the things LED brings is the security feeling to the cure, because it’s always on at the same power level. You never have to worry about the degradation of lamps. There’s also something thatís just the efficiency. LED is the most efficient energy-drying technology, whether you compare it to traditional UV, whether you compare it to IR hot air dry, there’s nothing that will reduce the cost of energy consumption in the plant like an LED system. It’s fresh. One of the other advantages, and a lot of our printers have remarked about this, there’s no odor or smell from the LED printing process because of the fact that you’re not putting heat into the materials, and you’re using a higher quality LED ink and an LED coating that doesn’t have the cheap materials in it that you see in some applications. So, there’s always a freshness to the product, which makes a big difference in the market. So again, you see just an ongoing example in this look book of different substrates, different imagery, and how it works together, and we just couldn’t be more excited. The technology continues to evolve. We’re coming with ñ as you mentioned earlier, newer generation spectrum combinations that allow for even more advanced curing, more efficient curing. They can also reduce the cost of some of the consumables in the process. But, the most amazing thing is just the value that LED can add to the offset industry, and how fast it can do that on existing machinery. And, we’re super excited. We’ve had this look book now that’s been here for just a few days. This is the newest printing of it, and we have a limited set of copies here at the Print Show in Chicago, but we’ll be taking requests to send them out to interested printers around the world as soon as possible. And, we’re happy to distribute this. We work with great designers, and a fantastic customers of ours that help us produce this. So, we’re very excited, and for them it’s a very exciting project to be involved in, as well