Michel Hunkeler · Over The Skype · Hunkeler

Hunkeler is by far the leading innovator in roll-based finishing, and with an increased focus on digital inkjet, the company seems to have a golden future. We got the chance to catch up with a good friend and INKISH supporter, CEO Michel Hunkeler, so here is his view on the current situation, and future.. Exciting, right?

As with all our ‘Over the Skype’ interviews, quality is limited to bandwidth, web-cams, and ability to literally LIVE mix the conversations. However, it works, and with Over the Skype, we will bring you more than 20 exciting people, and angles on the industry as it is right now.

Enjoy!

This is Morten Reitoft from INKISH.TV, and we are here over the Skype, which is our new series of films where we’re talking to industry leaders from all over the world. And today, I have the honor to talk to a CEO, Michel Hunkeler from Hunkeler in Switzerland. Michel, a very warm welcome to my little show here.

Thank you, Morten. How are you?

I am good. I was more curious about how you are because you are closer to the epicenter of European coronavirus. Is that something that has influenced Hunkeler in any way?

Fortunately, not yet. Of course, we see some influences in terms of traveling, especially traveling abroad, but our government is treating this thing I think very good, and allows people, especially companies that are of essential service to keep on producing. All our production guys still completely full, are producing. Everybody’s around. There is some risk people that we had to keep at home. And the office people, pretty much everybody’s working from home office. And no, we’re still in a good situation, let’s say that way. But we’ll see what’s going on.

Yeah. And does that mean that you still have demand for your products and services despite the global crisis?

Yes. We see a little bit slow down, that some of the orders are postponed now, mainly doesn’t have to do with us because our international sales engineer, of course, they cannot travel. But we still have a very good service engineers with all our distributors abroad. As you know, also in Germany, we have our own company, our own guys. And also here in Switzerland. They can travel to the customers.

But in general, yes, there is some postponements. We see a little bit of slow down in the order entry, let’s say, the last two weeks. But fortunately, we still have a very good backlog and are still in good shape. We’ll see how that situation will develop.

Yeah, that’s good to hear. On the other hand, I was very sorry because of the coronavirus forced Drupa to postpone till ’21, and that forced you to postpone to ’22 with the Hunkeler Innovation Days. And I wanted to go to Lucerne in February next year, but I can’t, at least not for Hunkeler Innovation Days.

You’re still very, very welcome to come to Lucerne and to visit us, Morten. You know that.

I might take you up on that one because I like that city and I like that time of year, actually. That could be nice. Michel, it’s good that you had the backlog. It’s good that you don’t see any sickness, of course. And also that, as you mentioned, that staff and family is in good shape, fortunately, and that’s good.

I was wondering, one of the things that I think a lot of people are thinking about these days, do you think that the printing industry and how we operate today, will that return to normal just after the coronavirus? Or will this have an impact on the longer perspective of the industry, you think?

Yeah, that’s a very good question that we’ve been discussing. Just actually yesterday, we had our management meeting. We were discussing that deeply. Of course, there will be some restructuring going on, unfortunately. We are sure about that, that especially weaker companies, not only printing companies but also suppliers of print supplies, of, of course, also finishing supplies that have been already in bad shape or not in great shape before, they will get some damage. We are sure about that. Yeah.

Is that something that you … Nobody can, of course, foresee the future, but is that something that you already now start considering how to adapt? When you produce hardware, especially, I know that you also produce a lot of software, but when you produce hardware, I think that the supply chain is a little bit longer. I think that the time to market is a little bit longer. I guess that you have to react quite early in all the signs that you get from the market. Is that something where Hunkeler is in a shape where you can easily adapt to new situations?

Well, our strategy especially now with the coronavirus actually, we kept our production fully running. As I said, we also purchased many goods. We are in a good situation that we have a good supply chain. Of course, there is some challenges in getting some of the products to produce actually Hunkeler machines then. But anyway, we were still producing, as I said before, to build up really a backlog because we expect large projects still to come, projects from big companies but also from smaller companies.

And when you look at the projects, we are looking who are our partners. And we are convinced all those partners … we have projects normally are already in the digital market. They already changed from analog to digital. And we are very, very convinced that they will be in good shape. The problems will be gone and as soon as it’s going to speed up again, we don’t want the customers to wait for us. We’re going to deliver right away. That’s why we’re building, actually, some machines on stock normally, without the coronavirus, we only make on order.

And when I spoke to you back at the Hunkeler Innovation Days, you said to me that the speed of adapting inkjet technology, especially took a little bit longer time than you anticipated. Is it your opinion that inkjet is now full ahead and there’s a huge demand for inkjet devices in the market?

Yes, for sure there is a big demand and that has developed very, very well. For 2019, Hunkeler has had the best year for last 30 years. We were very, very happy about the performance and what went on. And also, when we looked at the forecast or at the Drupa that’s going to happen, of course we are also in close contact with many of the big printer, vendors and stuff. We knew what’s going to come out, all that. Some already have been announced meanwhile. But yes, I’m sure it has come to a stage where digital printing is ready to go.

Of course there is always the challenge that there are suppliers of the printing industry in the world that maybe don’t really say the full truth, do some marketing stories about that. And that’s what really costs our industry some slowdown because it doesn’t help anybody if you make wrong promises. Some customers, printers are waiting then for that and then it’s not ready. And this is actually an attitude that Hunkeler doesn’t have. Usually, when we present something, we’re ready to sell, and we don’t do any wrong promises.

But anyway, coming back to your question, yes, I think, the digital inkjet to printing market is there. [inaudible 00:07:17] and yes, we are ready to go.

That’s great to hear. As most people are probably aware, Hunkeler has always been focusing on role-based finishing and obviously all vendors have role-based printing devices or bringing a role-based printing devices to market. But there seems to be a growing interest also for sheet-fed based inkjet systems. Is that something that you are considering entering into that market?

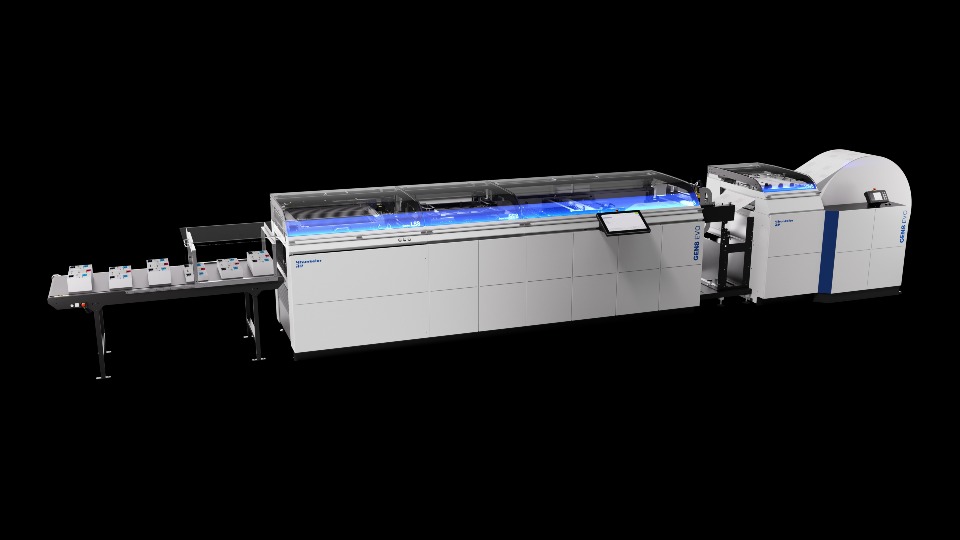

Yes, we are. We introduced that Innovation Days last year in Lucerne, we introduced the DocuTrim universal cut sheet finishing line, as we call it. And for us, this is a very, very important pass, not only we have the continuous feed but also supply our partners our customers with solutions, high technology solution, fast solutions in the universal cut cheat unit. And yes, I was very, very eager to see what’s going to happen now at Drupa, especially as you mentioned it.

Toner has been there for a long time, but the inkjet, what’s going to come new. We’ve already heard some announcements, some great announcements now that Drupa doesn’t take place, which is good, especially from Canada and Indigo, I can think about now. But the question also will be what format are we later on going to have, what’s the development of SRA3 going to B2, for example. In the inkjet segment, in the cut sheet segment, and I can tell you you’ll see a lot of good stuff coming up at Drupa 2022. And we further developed our universal cut sheet program, the DocuTrim. And yes, we are actually ready to go also in this segment.

Sounds great. I did an interview with Hayco van Gaal and a Jutta Hendrikx from Canon a couple of days ago that was published today. And I actually asked him about B3 formate of the new IX series because I think that if you look at the Indigo machines, they have the B2 sizes. If you look at both Lambda and Konica Minolta, they also have B2 sheets. But as I think they said quite good actually is that nobody’s really … If you look at the finished product, the finished size, maybe the bigger formats are more a legacy of the past rather than what is needed today. Maybe it’s about speed and maybe it’s about the finished product rather than the format.

Of course, that is something that you take into consideration as well, but do you think that assessment that Canon has is correct or is it just because they need to sell their machines with the B3 format as it is?

No. I think it’s correct. You never know what’s going to bring out later on also, maybe in the B2 format. Of course, I don’t know that, but in general, I think most volumes still are in B3 [inaudible 00:10:21]. And also, to catch up speed and everything, to produce various products, B3 is good. We personally believe, especially in the book segment, that B2 will have its place. Of course, we all know inkjet has a lot of water on a paper to handle those big sheets then actually, is not that easy. Especially, the question will be then is it inline to the finishing, is this near line, whatever.

Yes, as I said before, also Hunkeler will thinking about going into the B2 format. And right now, B3 of course, is the biggest volume, but I’m sure there’s many customers waiting also to have a good a solution in B2. I’m definitely sure about that.

Yeah. One of the things that I always liked about Hunkeler’s approach to finishing is that you have a very modular build up of your equipment. You can basically configure to almost every application and to every output device that you need to work with. Do you think that when you look at, for example, if you look at the cut size or the cut sheets machines in the market, I sometimes think that if you have a cut sheet machine and you, for example put in a perfect binder in that inline, then the machine becomes a little bit limited because it’s then inline only. And the cut sheet machines are way more often used as very, very different devices with very different outputs where you have role bases maybe more based on one or a few applications. Can you follow me and what do you think about that?

Yes, absolutely. I agree. Yes. Also, when you especially look for maybe also the price standpoint, some machines, especially in the toner now, maybe not in inkjet, but there were also from an enterprise standpoint, down to create an interface, to build these two segments together, that costs a lot of money. And if you’re going to change to [inaudible 00:12:20] or maybe also change to finishing, just to create a such an interface is actually quite cost intensive. Yes. We always say from the process security, of course, to keep up the control of the product from the start to the end, it’s better to go inline. But both ways have its standings.

Yeah. And that is, of course, something that you may know more about than you can tell, but I think that it’s quite interesting because one of the other things that I also find quite interesting every time you talk to vendors that produces inkjet devices, initially when you have toner-based equipment, they kind of fight for a smaller part of the market because they fight over market shares in toner-based, which is still a very small part of the global value chain. But if you look at the inkjet devices and the speed and the quality and the capabilities these machines have now, now we see people that are trying to get a chunk of the offset market. I guess that is a huge opportunity for for Hunkeler as well.

Yes. It is, and that’s exactly why we decided to enter this market. Overall, seeing many [inaudible 00:13:40] about continuous feed. Finishing in the perspective of many people years ago, maybe was not being as important as a printer is. Of course, the printer is very important. No doubt about that. But the value of having a good finishing solution, a reliable finishing solution, has increased last years. And I think it’s the same also with the cut sheet, that the machines are getting faster, higher quality, better coming to inkjet then also. And yes, there will be more and more demands coming. Maybe it’s not that there yet.

Many printers might start having just the press installed. But I’m sure with the time and with having reference cases out in the world, seeing, hey, what are the added values of such an inline or also near line finishing that’s really high automated and technology-wise really stable. Then I’m sure there will be many customers also saying, “Hey, yes. You also need to think about the finishing.”

Yeah. I have always thought that finishing was, at least for the past 10 years, been more important than the print because print has a very, very high quality regardless of technology today. I think it’s very much about when the printing companies is either focusing on a few applications or having a more commercial printing go-to strategy, then things change. And that is one of the reasons why I’m a little curious about the cut sheet finishing, because if you look at what happened with toner-based, I think that a lot of the vendors in digital, they thought that, okay, now we’re going to do mass customization and variable data and all that things.

But actually, a lot of the toner-based devices has taken, I think a quite big percentage, at least in the smaller markets of what used to be printed in the offset machines. It’s been more of the short run that has been driving the digital demand rather than the mass customization, in my opinion.

Yes. And of course, also to have variable substrates right away, although this is, I think, is a key that officer never could provide, change over times and all that. This is a really great value. Yes, and we are so convinced that the inkjet cut sheet will have its good place in the world and will be a good option to continue, as you know. And the best is of, course you, have both. And we see, really, many customers, many projects that we also talk with them about of DocuTrim. It’s a together, continuous end cut sheet. And this is really going to bring a lot of values.

For example, you can have a cut sheet device for covers on a book and then the role-based for the content, right?

Exactly. Or doing reprints, but of course inkjet cut sheet machine’s not only there to do reprints, but yes, as you said, the covers and just to do a small [inaudible 00:16:42]. Maybe that day you don’t want to wait for the whole roll to be finished, let’s assume it that way, and so on. There is so many business cases. You can mix them together. And that’s why Hunkeler decided that we also want to actually be a good provider of good machines in the segment of cut sheet.

Great. Now, I would like to ask you a little bit, because if you look at the market, we should talk about the opportunities and how great it is. And as a global supplier of finishing equipment, do you see big differences in the demand in, let’s say, Asia, Middle East, Europe, Americas, or is it quite even?

Well, from the tradition, Hunkeler has been always very strong. [inaudible 00:17:28], of course, we are in Switzerland. This is the center of Europe, and it’s just from the history, we’ve always been very strong.

I thought that was Copenhagen.

No, no, no, no, no. Hey, look at the map [inaudible 00:17:38]. We’re going to discuss that later. But anyway, yes. Europe for us was always the strongest, but we’ve seen the last three years huge, huge development mainly in Americas. Of course, also EMEA has that. Maybe EMEA was in certain points a bit further developed already inkjet. But in US, we’ve had a tremendous success the past three years. And last year was just tremendous. And not only large accounts that have multiple production sites, it’s also smaller customers that really changed from analog to digital or actually build up their capacity digital also.

And Asia Pacific, we’ve really felt … We were very successful, especially the books segment also in China, for example, with the generation eight all over Asia Pacific. Also in Australia, we’ve been quite successful. But we’ve seen there a slowdown, a little bit a slowdown. But when I look at the project list, I think it’s coming again. Yes.

When you plan your things, what is the time perspectives, because you talk about the backlogs and you talk about the projects that you can see coming in. Is that often, sometimes three months, six months, 12 months? How long time do you kind of forecast when you are talking about development of products and services?

Are you talking about developing our products or a project?

I was more thinking that you say that you look at Australia, you look at Asia, you look at EMEA and you look at the US and you see the development. Of course, you can see what you have invoiced and sold. But I guess that you also have an idea of what’s going to … because you have, I guess you have some kind of ideas of what projects and what pressers are going to the market. I was just wondering what is the prospective time-wise when you go into a sales process with the companies that is the selling cycle like a three months period or six months. How was it often in the decision processes of Hunkeler equipment in your opinion?

Well, to bypass a little bit the question, what I love most is of course a spontaneous decision that we haven’t expect. We go into projects, “Hey, what’s going on here?” We can deliver already in two weeks or so, or not deliver or start production, close the deal, have a PO in our hand. But normally, of course, life cycles of such projects are longer. I would say in large projects, some of them take more than a two years that we’ve been working on.

Oh, really? Okay.

But it’s just the decision path of the costumers. Maybe they’re not very happy about the development of different products. Maybe also price-wise, they cannot decide if they want to change their habits in all the IT tools and so on. But yeah, some are very, very long. But I would say just in average for us, I’d say lead time from the start to the delivery, I’d say it’s about three months.

Okay. At least you know a little bit about what’s going to happen in the next three, four months from your perspective now as we speak.

Yes. Yes.

That’s great.

We hope so.

Yeah. We hope so. Michel, it’s been a pleasure to talk to and get a little insight in the Hunkeler world. As I said to Hans [inaudible 00:21:20] many times, I would really like to come and do some frames from your production. I think it must be so interesting to see how you do things. Whenever it’s possible, I hope I can get an invitation to come and see you. That would be nice.

Morten, we appreciate what you’re doing, so you’re always welcome. Let’s discuss about that, of course.

Thank you very much and have a great day ahead of you.

Thank you very much. Stay healthy.

Yeah, and you, too. Bye-bye.