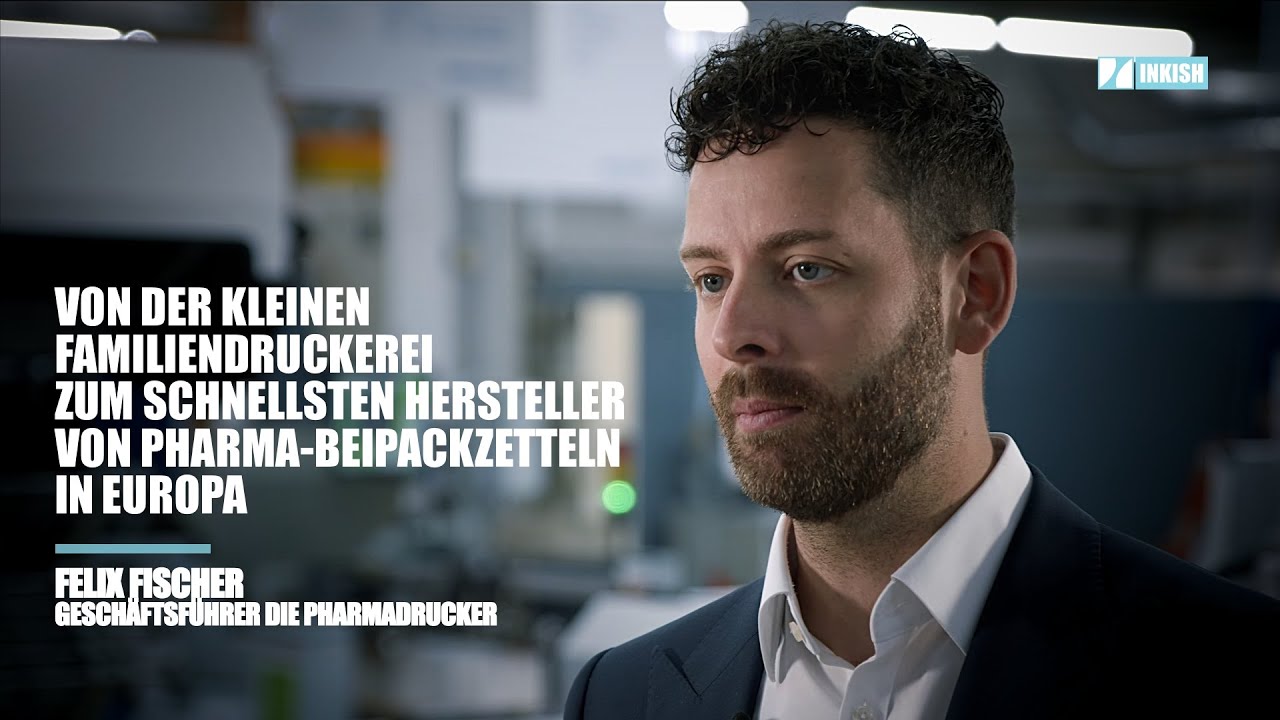

Felix Fischer · Managing Director · Die Pharmadrucker

German edition click here.

A small, family-owned printing company in Germany focuses entirely on pharmaceutical and cosmetics printing, with a strong ambition to be the fastest producer of pharmaceutical leaflets and instructions for use. The business originated from a concession to print a weekly newspaper, which served as the foundation for the Bernecker family’s printing activities. For decades, print news remained dominant, but over the past 20 years, the industry has changed significantly.

Despite the company’s heritage and long-term direction, recent global instability has shown that outside forces can quickly disrupt small businesses. The pharmaceutical focus began roughly ten years ago, though they had handled related work earlier. Over time, customer needs and available production technologies pushed them further into the pharma niche.

Finding skilled labor in Western Europe is difficult due to demographic change and fewer young people pursuing manufacturing roles. The company attracts younger workers with its flat structure, but must invest in training. Pharmaceutical print remains highly specialized even though it still involves printing, cutting, and folding. The substrates used are extremely light—40 to 60 gsm—and require technical adjustments, new processes, and training to manage. Their promise of fast delivery — often within 24 hours and typically within 10–15 working days — sets them apart. Their small size and short-run focus make this speed possible.

To support this model, they are transitioning from offset to inkjet, eliminating plates, chemicals, and various mechanical components. This shift improves turnaround time, maintenance needs, and sustainability. The company’s folding work is highly complex—often involving more than ten folds—and few machine builders can support these requirements. H+H became a partner because both companies shared the same development goals.

Their configuration includes rotary cutting followed by complex folding. The M9 folder automates pocket adjustment, appealing to younger employees who expect touchscreen functionality. Operators still fine-tune settings, but setup time is drastically reduced. The company sees itself as a development partner, helping refine both folding and thin-paper inkjet solutions. Implementations required collaboration, careful communication, and rapid response to issues from the technology supplier.

The production setup delivers major benefits: faster operation, fewer processing steps, fewer operators, reduced error potential, and greater value creation in a single line. The move to inkjet also eliminates heat as a production factor, which they note as significant.