Down to the Copy of One · Volker Leonhardt · President & Member of the Board · Müller Martini

The printing industry is all too measured by the developments in printing technology. Ultimately, however, postpress determines the quality, quality and effectiveness of a print production.

All the more exciting the Over the Skype conversation between Volker Leonhardt, President and Member of the Board, Müller Martini AG, with Andreas Weber, CEO INKISH D-A-CH.

From the provider of mass production solutions i. e. in the newspaper sector, the solution provider based in Zofingen, Switzerland, has become a top player in on-demand and short run productions. Target markets range from on-demand productions to the manufacture of digitally printed books. Made in Switzerland is becoming a quality mark all over the world.

What sounds like squaring the circle is explained by Volker Leonhardt as a logical consequence of turning to Industry 4.0. The digital know-how is used in new, ultimate solutions and in the handling of services and spare parts delivery.

—

Die Druckbranche misst sich all zu sehr an den Entwicklungen in der Drucktechnik. Doch letztlich bestimmt die Weiterverarbeitung die Güte, Qualität und Wirkungsweise einer Druckproduktion.

Umso spannender die Over the Skype-Konversation von Volker Leonhardt, President and Member of the Board, Müller Martini AG, mit Andreas Weber, CEO INKISH D-A-CH.

Vom Anbieter von auf Massenproduktion ausgelegten Lösungen v. a. im Zeitungsbereich hat sich der in Zofingen, Schweiz, beheimatete Lösungsbieter zum Top-Player bei On-Demand und Short Run-Produktionen. Zielmärkte sind anspruchsvolle Produktionen bis bin zum Fertigen von Büchern. Made in Switzerland wird zum Gütezeichen in aller Welt.

Was wie die Quadratur des Kreises klingt, erläutert Volker Leonhardt als logische Konsequenz in der Hinwendung zu Industrie 4.0. Das Digital-Knowhow findet Anwendung bei neuen, ultimativen Produkten/Lösungen und im Handling der Services und Ersatzteillieferung.

LinkedIn profile https://www.linkedin.com/in/volker-leonhardt-5b887419/

Hi INKISH folks! Andreas Weber here in Switzerland in the most beautiful town of Switzerland, in Zofingen. And I’m here with Volker Leonhardt. He’s in charge of Müller Martini. And we want to discuss the beauty of a topic which is maybe not that common: it’s about finishing, and finishing 4.0.

Welcome Volker! And thank you for sharing time with us.

Thank you very much Andreas.

And as I said before, my very first impression of Müller Martini is something like decades ago, when, as a young man, I came to a newspaper manufacturer and I saw a big installation in the mail room and I was fascinated by that.

But I think this is maybe 30 or 35 years ago, things have changed dramatically.

So what is your biggest challenge today in the digital age?

Well, as you said, the newspaper is still one of our divisions.

Unfortunately, not as big as before, as the newspaper products are declining the most, even though the print volume globally is by far the largest.

However, if you talk about digitalization, we already had workflow systems in place when it came to newspaper production. Maybe you recall the times of microzoning where you insert the free-standing inserts according to the target groups.

Absolutely, yes. So versioning and what we today would call [unclear] mass customization. From that point of view, it’s an old topic for you. But also in the meantime, we have, you said, changed.

I think we have different new things coming, showing up. So for sure, we still have mass production in the printing industry. And I think you are the best partner for that.

But on the other hand, digital printing has also a big impact. Maybe you can give us an update on that?

That’s correct. On one hand, we have our very traditional type of clients with a very large installed base, when it comes to saddle stitchers, perfect binders and thread sewing machines.

But as the clients transformed their business towards digital printing, the need was there to have the most appropriate finishing kit, which we delivered over the time. So all of our products are digital already.

They can be hooked to whatever digital press, for instance. We can consume digital print output and have it fed into our machines and even more, we also developed a workflow system which we call Connex, that consumes the customer data, translates it into our machine language, and then we have a report function back, what we call Connex.info so we know what’s going on in the finishing department.

That means in the meantime, you have a highly digital competency inside Müller Martini, because normally you wouldn’t expect that. And when I go back in my memory, I can remember that I visited Books on Demand in Hamburg and their production facility and for sure Müller Martini was part of that, beside another charming Swiss company, Hunkeler, we all know and love.

Maybe you can explain a little bit how that happened and what is crucial for being a partner in this environment?

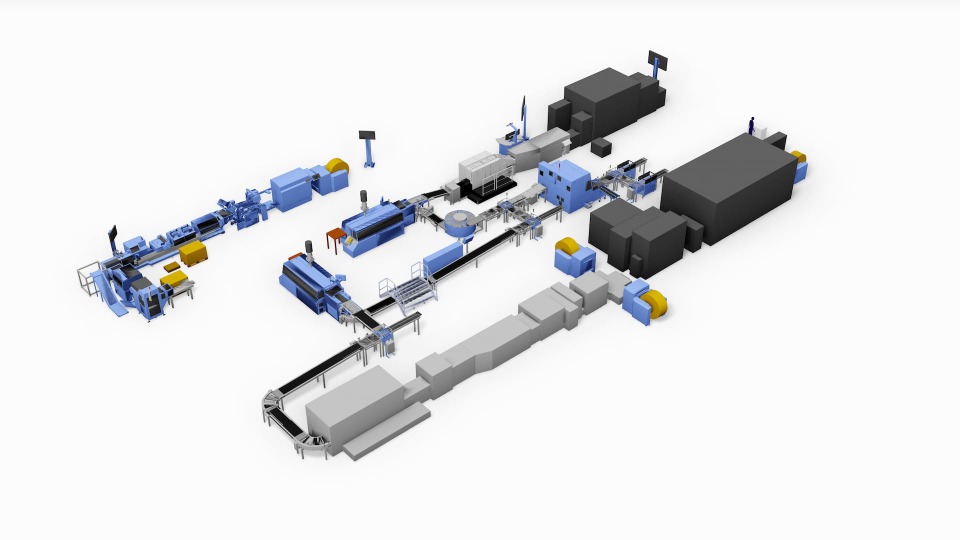

Well, in fact, we already started in 2004 with a digital device, SigmaLine, that produces a book plug. And the demand was driven by the very large publishing houses in the US because they wanted to get rid of their warehousing. That was the main driving force behind the development of the SigmaLine.

And over time we developed that machine and enhanced it.

And ever since 2010-2012, I think, we delivered these machines into the market.

That is a very large machine that produces a book block. And over time we stepped also with our saddle stitchers and smaller perfect binders into this area.

So you have all the portfolio that is available at Müller Martini being digital ready, as I said before. And with our latest developments, we have also book of one capabilities, for instance, or product of one capabilities.

And that means so…time to market is an issue. And you mentioned the publishers. They donât want to have books on stock anymore. So you have to deliver fast, high quality and for sure, for a good price.

Absolutely. I mean, there are a lot of applications around like photo books, like educational materials, like self published books. That does not come in large quantities, it’s rather one or two of each product that needs to be produced.

However, in large quantities, if you wish.

And that is capable⦠or that is possible on our machines, yes.

And what kind of team; what are the skills inside Müller Martini to be able to create those workflow scenarios. And I can imagine these are complex scenarios because your cover not only your area, you have also the whole print production, and the premedia process is also part of that.

That’s absolutely correct. Well, to start off, we have a fabulous engineering team with solution architects. So they partner with, for instance, the press manufacturers, digital press manufacturers. So whenever a client decides to go with a large web press, we need to incorporate that into our workflow system.

That’s where the solution architects come into place, these are R&D people. And then we have solutions set-up people when it comes to consultancy of our clients, we have a team of people that analyze the customer demands and then we can work out the most appropriate solution to our clients. It’s always a team approach.

And it’s always very tailored to the customer needs [unclear], right?

It very much depends. Various machines like, as I said, for instance, a thread sewing machine that is capable of consuming digital print, cut sheet print, for instance. That’s more of an out of the box machine. That doesn’t vary too much. When we talk about very large book block production systems, like with the SigmaLine, that needs to be incorporated into a very specific client’s workflow, then of course it’s much more tailor made.

I would say it very much depends on the size of a project and it of course, depends on the specific situation of a client. But we can serve both worlds.

And thatâs great to hear because needs are the measure of all things for sure.

And what I’ve learned as well when you took us around… thank you for that tour across all those beautiful halls here⦠and also the part: servicing your customers, giving them technical services, spare parts and so on. And therefore, you also need a highly developed digital competency, is that right?

That’s correct. For instance, we have our spare parts online shop where clients get access so they can order spare parts via our webshop that will be automatically transferred in our SAP system, the parts can be picked here, downstairs and be delivered to our clients.

And I think those clients, they come from all kinds of areas. So not only specialists for bookbinding and finishing. What about your relationship to, let’s call it the e-commerce world? Or we talk about book publishing? And I think e-commerce is also good for that. When I think about photo books or backlist printing and so on.

Maybe you can give us some more insights into that?

Of course, our clients are mainly the producers. Sometimes publishers do maintain their own print shop. That’s where it comes together. On other occasions, it’s more diverted. I would say, you mentioned this client in the northern part of Germany where they have a publishing house as well as a print shop.

Of course, they have their own systems. We don’t deliver these systems, but we can hook our systems and consume their data.

We will translate it into our machines data and then produce the products and then have a proper reporting back into their systems so they can retrieve production data, for instance.

Because I think that’s a very important issue for doing the Books On Demand business, because they have to cover ten, fifteen, twenty, thirty thousand different books per day in their production hall.

That’s correct. If you compare, I would say the conventional production to more the digital type of production: of course, you have much more jobs that you need to run through your production each and every day.

That’s what we call the print order; what was formally put into the physical print order that needed to be digitalized. That’s what we did. We consume that and bring that into the production environment.

And I think it’s important to understand: how are you able to do that? That means, what kind of skills your company needs or what kind of partnership are important for Müller Martini?

That’s what I said before. We have an R&D department, we have solution architects. They work together with our partners. Be it on the press side, or be it on the ERP side. So we are capable…

So they are more digital natives than biding specialists…

Exactly. They are probably more digital natives. At the very end, it’s the combination amongst the teams.

You have to have the specialists understanding the workflow part and then you have to have the specialists understanding how you physically produce a book.

And that’s where it falls into place. And I think that’s the beauty of having such teams that kind of support each other.

And I think on top, you need a lot of knowledge and good connections to all kinds of print technology manufacturers.

That’s correct. We do it the Swiss style, I would say. So there is no exclusivity and nothing. Whenever a client decides for this or that press manufacturer, we will implement our system into their… or their machines into our workflow. Be it HP, be it Kodak, Xerox, Canon. What have you. We even integrated a press manufacturer from China. So we are open to that. We take our time in order to have everything proper implemented and then it will become a good solution to our client.

And this is not only related to what we call inside the Inkish industry of 3.0, where the focus was to optimize internal production workflows.

But it’s really industry 4.0, you name it, finishing 4.0 where everything becomes open and connectivity is key, right?

That’s correct. We are strong believers of open workflows. There is… I think there is no room for closed workflows, for proprietary workflows. You need to be open in order to serve the markets best. That’s correct.

And another keyword is end to end solution. So no more disruption, no breaks. How far is that? Because especially in the field of digital printing that talks about in-line finishing as well, how is that? Are you able to be connected to any device?

That’s what we do. That’s what we do. We are strong believers in end to end solutions as well. We call it âPDF in, finished book outâ. That’s what we do. Of course we don’t deliver the presses; that comes with our partners, but from the press or behind the press, we consume paper and merge it into finished products.

And therefore, I’ve heard that in your system world there is a certain intelligence which I find very smart. Because the tricky thing is when… let’s say, in the digital printing process, something goes wrong. Your system has to communicate: âOh, stop! Please redo itâ. Right? Automatically, yes?

That’s correct. So we can do⦠we ask for a reprint if we experience whatever kind of mistake or faulty book or something like that, we can ask for a reprint.

So it’s a fully integrated workflow system at the very end.

And what is your feeling? What we are talking about: is that maybe for many people in the printing industry, is it a little bit far away? Independent from the fact that everything you talk about is a fact? It’s not a vision. What do you think? How is the perception in the market? Because you also act on a global level. Are there differences between the continents? Are the differences between different market segments?

I think the reason Covid-19 pandemic kind of accelerated the digital transformation…That’s what we see actually all over the place.

Even clients who were very reluctant before when it comes to transforming their business towards digital print, they become now much more open.

I think the basis for that is a much better print quality that you see in inkjet now.

So it becomes much more accepted. I think there is no difference at this point in time. If you would compare it to offset printing.

I think clients work much more on their business model. And that’s why they rethink stepping into digital printing, and that’s what we see almost all over the place.

We recently sold a very nice SigmaLine installation to Asia. You would probably not expect them to move as quickly as they did. But they did it.

They did it for purpose because they had worked on their business model. And they saw a very good opportunity there.

And do you have to stimulate those customers to get close to you, or is there automatically a demand from the customer base asking you?

Well, I think it’s a push and pull, of course.

We have our market organizations being active, our [execs] regions with which we cover the markets. We work on our clients each and every day.

On the other hand, we work very much now with social media because there might be new clients, new kids on the block, not work with Müller Martini before, probably not aware of what we are doing.

That’s why, again, thank you so much for giving us the opportunity to present ourselves. So that’s why we work very much on the customer journey, because these new clients need to be stimulated probably another way and they would not expect Müller Martini being so advanced.

But⦠so, when I got your message right? At least there is still hope for the printing industry and let’s say, Covid is a catalyst for speeding up the digital transformation processes.

And then you’re offering must be loved all over the world, because in my opinion, you stand for really covering the needs of industrial production.

That’s correct. I mean, we serve on one hand side our very traditional long term good clients, very conventional clients, of course.

And on the other hand, you have the new segments like the digital kids starting their businesses and then you have those who are transforming their business. Of course, there’s hope.

However, there’s also… it’s a tough environment these days. I think we will see more consolidation as times come. But there is a very good opportunity, still, also for people like us.

That’s good to know. And always a question in those conversations – and thank you very much again for having us here – is what will be the next big thing? Besides the fact that everybody has to stabilize the current business situation, but for the whole industry, what do you think? You mentioned inkjet printing, but that’s already given.

So, I mean, something on top? Do you have something in mind?

Well, I think, as you said, it’s the integration into workflows, into ERP systems. All that is a very big thing. I think Web to print is still very big. Self-publishing seems to be a big thing. And then, there are still a lot of clients out there not using digital at all.

And I think that is a big opportunity. Once these clients will transform their business, we can support them. We offer our services to these people. Hopefully that will work out for us.

And maybe because we know each other, weâve been knowing each other for 20 years and longer! When you go back to that time, would you have expected things getting developed like this coming today, or was the expectation at that time totally different?

Well, a lot of topics that we discussed somewhat 25 years ago are still very hot and actual. They are still on the short list: fast turnaround, versioning, one to one communication.

I think that is still a big thing. I somehow expected the transformation to be faster.

Me too.

I would not have expected companies from this end, like Müller Martini driving applications so fast and so… with such a steam as we do. I would have expected much more the press manufacturers. So I’m very proud of being part of this journey and I’m really looking forward to further developing the market.

Thanks for your kind words and I think both of us, and all of us can be confident, even if things run sometimes a little bit different. But who knows? No risk, no fun! And thank you for having us here. And I hope to talk to you quite soon, again, to see how you make progress, because in our world, your topic finishing 4.0 is so important for our Smart Factory initiative. And maybe we can go more in detail later on.

Yes. Thank you very much Andreas, and thank you to the INKISH team. Thank you.