AMS Spectral UV on Merging with Baldwin

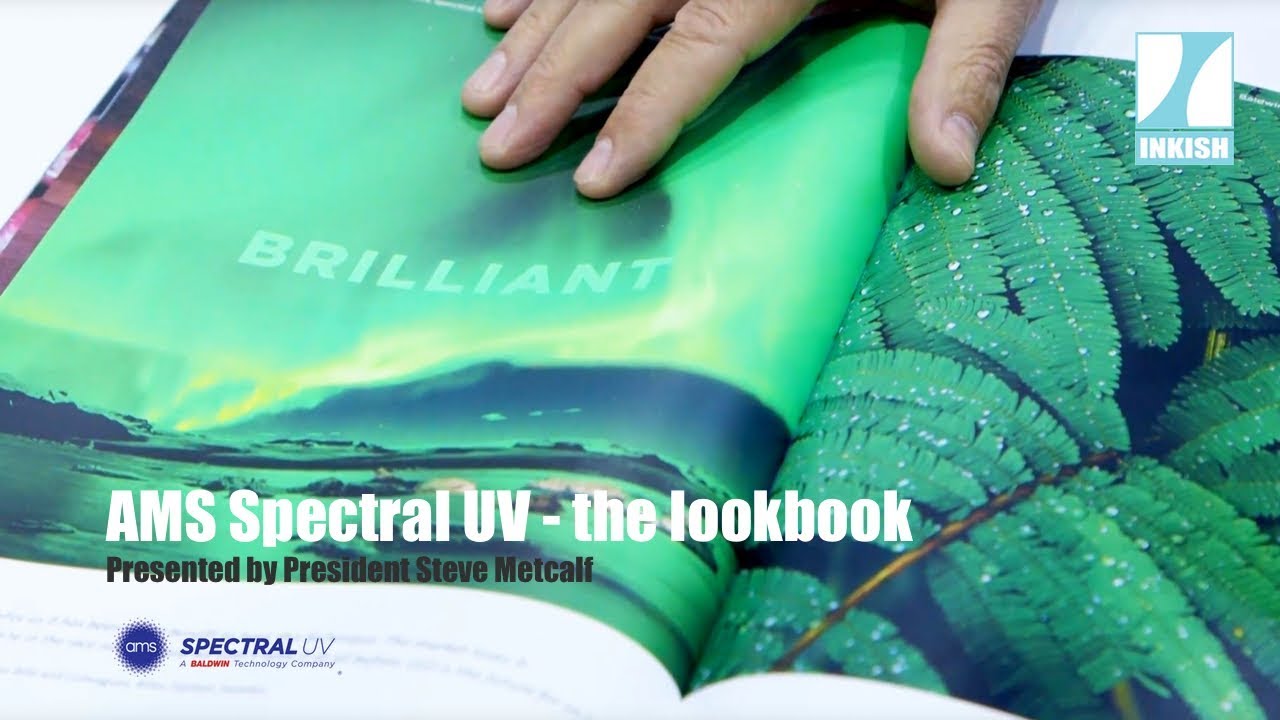

AMS Spectral UV was acquired by Baldwin Technology Company almost a year ago and INKISH got the opportunity to go to River falls in Wisconsin to talk to President Steve Metcalf and more people from the company that used to be known as Air Motion Systems. AMS Spectral UV is one of the world’s leading developers of LED-UV curing systems and has been extremely successful over the past years. In this film, we get an insight into the potentials the acquisitions give AMS and also how it has influenced Steve Metcalf who has spent a major part of his life in the company. We hope you like the film!

AMS began a number of years ago, it was in Colorado for a good period of time, but in 2008 we relocated here to Western Wisconsin. Really, what we set out to do was to create a new generation of our company to support the new generation products and technologies that we were working on at that time. We’re at an area that’s very economically diverse, and so we have great access to skilled people and all of the manufacturing trades and areas, as well as engineering, mechanical, electrical engineering. Everything in this building is environmentally more friendly than a normal building.

It’s a LEED certified building, which stands for Leadership in Energy and Environmental Design. It’s a concept on how you design and build a building that makes a friendlier workplace, a greener environment, a more energy efficient, but also just a more pleasant environment with a lot of natural light, a lot of things that are conducive to having just a great workspace. We found it extremely effective to develop our technologies at a faster pace than, I’d say would be, typical if we had done it the old way. We also have this core belief that if we talk about technology with our customers that is fundamentally green technology that allows them to be more environmentally friendly, efficient, etc, we got to be also living that purpose ourselves.

We have, in this site, approximately 50 people that work here on a daily basis. Some are out in the field for us, some are back in, but we’re part of a much larger organization, as you know. We have a sister company in the UK that’s also based on a lot the same principles of design and manufacturing that we oversee as part of AMS Spectral UV. We’re also backed by a much bigger company known as Baldwin, which a lot of people are familiar within the graphic art space. Baldwin is now one of the fastest growing companies in the industry that’s not manufacturing primary machines. Baldwin is engaged in all kinds of the component and process technologies, from cleaning systems, to spray systems, to corona treatment, to UV, LED, infrared technologies across the gamma.

They gave me about 30 days at a facility like this and we start really opening up about the processes and we start understanding and making fun of ourselves where we can improve processes, next thing you know, a lot of great stuff comes out. A lot of team mates bring a lot to the plate and they’re dying just to get their voice heard, and that’s what my main role is. It’s just to give them the opportunity to have their voice heard.

The Baldwin combination with AMS was very important, very critical in the market, and we’re almost on one-year anniversary of that acquisition. To have the resources and scale that we can bring together from our acquisition with Baldwin was really key for us and it’s working so well. We’re bringing technologies now that are going to be announced this year that would have taken us a lot longer to get to without that combination of skills and resources.

As you mentioned also, there’s a nice part of this which is keeping growth into scale of the manufacturing outside. You know, as our company was growing, the pace of our market growth rate was starting to outstrip our ability to bring in talent and resources from manufacturing and operation side. One of the great things about Baldwin is they really have an expertise, and it comes from the larger company which stands behind Baldwin which is Barry-Wehmiller, which is our big family of companies.

Barry-Wehmiller is a $2.5 billion organization with over 10,000 teammates that are out there. We have this unique people centric culture, where it’s not management driven, etc, it’s about teams, it’s about building our people. We have a lot of great people, we just got to teach them to be able to work as teams and we can get really good stuff there. From a leverage standpoint … You’d think with all these different divisions, we have a supply chain, we all have the same supply chain, we have best practices at each other’s facilities, we have some great things going out there.

From a benefit standpoint, AMS Spectral benefitted from Baldwin, and Baldwin benefits from Barry-Wehmiller, and we got this huge team that’s out there that we just constantly keep moving the business a little bit further every day. Vice-versa, Baldwin really benefitted with the AMS Spectral team, too. They have some great customer base and Baldwin opened up a lot more for the AMS Spectral team, too.

We have a combination of every function under this roof as we do in our sister companies, all the way from engineering to the design of the products, the manufacturing of the products. The inventory, their logistics, shipping and handling, all of the support functions, marketing, our customer service, everything that goes into sort of keeping our customers running is also here too, and we coordinate that across sites. We have an R&D team that works closely together with our sister site in the UK and they’re connected every day via video conferencing. They talk about new product developments, we leverage people’s strengths. If a certain engineer has an aptitude for a certain type of electrical engineering, we’ll put them on a project quickly.

The machinist and myself work very closely with engineering. They make the final say on the part and how it’s going to be produced, but we have a big saying that, as far as helping it makes sense financially, how fancy doesn’t need to be. We help engineering find maybe the better way to fabricate it, what material, what design, stuff like that.

Getting ideas is pretty hard so you have to be creative. One of the things that’s really nice about working for AMS Spectral UV is that we’re allowed the time to be creative. Whether we work on the art side of things or we work on the mechanical side of things, that kind of blend allows us to innovate and make new ideas.

We do certain parts here and only here because we do them best. All of our prototyping type parts get done here, because they’re usually in small quantities, we can do them cheaper. Parts that get made outside of here is usually because we can’t, like sheet metal, maybe really large weldments, large run quantities, stuff like that that doesn’t make sense to do here. We are more of a prototype shop than a mass production shop. Our shop is equipped with four CNCs, three which are Haas machines. One of them has a 80-inch cut length, so we can do very long parts, we can also do very intricate small parts. There’s really nothing that we can’t fabricate here, even if it’s once or twice.

To make the tightest form that we can so that we can fit in all of these different types of printing presses, we water cool our LEDs, and so that allows us a lot of flexibility as far as size. Air is kind of a funny animal, it requires a bigger size, so that’s why we’ve pretty much stuck with water-cooled. Yes. A higher energy allows less expensive inks. If the ink prices go down, the printers can print more, faster.

Our wide spectrum series allows us more flexibility, especially because we work with all of the different ink companies, so we don’t hold any ink company above another. If they want, they can bring their products, we can do some testing, or we can go to their facility and do some testing. Then the different frequencies allows the chemist to use different photo initiators, which is the real cost of the ink. It’s not so much the pigment, but it’s actually the chemical that starts the process that makes it more expensive.

There’s a lot of mechanical stuff to it, but there’s a lot of electrical stuff to it, too. I mean, all of the LED controls or UV control systems, and we do all of our own custom build control systems here. It’s pretty equal, 50-50, I think, electrical, mechanical.

We definitely have the strongest footprint in the sheet-fed printing market. There is no other product in the world that is built for the rugged requirements of sheet-fed offset printing like our LED system. That said, we are every day gaining larger and larger footholds in other markets. Flexography, we do work in digital printing, and curing of markets outside of printing as well. It’s, every day, the market for LED is growing, but its strongest foothold remains in the printing industry. The great thing about AMS is we are willing to work with our customers and determine how much assistance from us that they need to be able to understand and operate the technology.

Some printers are, by nature, going to research and investigate by themselves before they even communicate with us, and they’re going to understand how the technology works the minute that they make contact. They’re going to say, I understand the features, the benefits, I want it, so I just need you to get a system that works for me. We also see the other side where people hear about it, but almost don’t believe that everything that it’s capable of is true, and so then they contact us just trying to help themselves through that research phase.

Yeah. I mean, you’re putting equipment on these multi-million dollar presses and your equipment doesn’t cost as much as the press, but if your equipment causes downtime to that printing press, that’s a huge deal. You got to make sure that you don’t cause downtime to begin with, and if there’s something ever does go wrong, then you’re right there to get it back up and running again. We have a lot of really good dealers that are all spread throughout the globe that definitely help us out with customers and meeting their needs when that need arises. Now, being part of Baldwin, too, we have a lot more global presence. You know, we have the office near London and they have service techs all over here, which helps a lot.

It’s crazy because everybody kept saying that this printing industry was going down, so I jumped ship from the Barry-Wehmiller side, the packaging side, and I don’t see it going down. If anything, it’s just tons of opportunities out there to improve the printing that’s out there. I’ve been given the chance to work with these guys here with the state-of-the-art equipment they’ve got. I mean, this has been a lot of fun. It’s interesting as that we got these main strategies that we want to grow Baldwin. We’ve got a certain percentage just going to the organic route. We also understand that the printing industry is not as big as it used to be, so 30% of our growth is really focused on using our printing technology to other avenues that are out there.

If you look at the corrugated industry, with the boxes and their printing stuff, so we have one facility that provides the dryers now for the corrugated industry. We have another one where we got the infrared, UV technology that’s helping with the yogurt cups and sterilization and that type of stuff. It’s really about the, hey, we went to organic route, we do have acquisitions also, we do always look for opportunities to keep growing Baldwin from a acquisition standpoint, but we also got the new product development. You know, we have technology we want to be able to use outside the traditional printing industry also.

You know, the hardest thing that we faced is being able to reach the printers. There are a lot of people who we’ve been able to connect with through trade press, trade associations, but the large base of printers who don’t participate in those mediums still have yet to learn about the technology. Our big challenge is figuring out different ways to get the message out so that people understand that this technology really will revolutionize their printing operations, make it so that they can offer their customers a better end product and, in the long term, will be a sound environmental investment for their company.

It’s a lot about what we can bring to the table. Now, we can start bringing a whole package to the table. You know, we don’t own the printing presses themselves. We’re kind of the OEM that bolts things on with the printing presses. Now, we have our cleaning, we have spray, we have the curing. With this team here, we’re bringing a lot to the table. When you’re with Baldwin itself, is that you’re getting the whole package. You’re getting the parts support, you’re getting the service support, you’re getting the ability, from a technical standpoint, to solve a lot of problems, and really help the printing press, the main customers there, build other equipment, sell more product. It’s more about our partnership.

You know, our partners are one of the greatest assets that we have as a company. Being able to work with the ink companies, we consider our customers our partners, and a lot of OEMs out there are our partners. It really expands our ability to get this technology into the hands of people who need it so that they can better their business and eventually become more profitable themselves.

It’s really just keep doing what we’re doing, just execute it a little bit better. We’re constantly bringing out new technology. We got this big business unit review next week at the sister facility over in London. It’s really about, you know, this was year one, what’s year two look like, what’s year three look like, and it’s constantly moving the needle up a little bit higher. Our goal here is that we want to have a 24-hour a day operation, two more shifts, and just keep bringing the business and building our foundation for our people just to keep growing.

We’re owners in a much larger family now, so we actually have strength in numbers now. We’re still very much, let’s just say, committed to the business from a standpoint of, if you would, if you were an equity partner in any company. There are definitely things that have required sort of an adjustment to a new system, but ultimately most of these things that we adjust to now in a bigger family are very positive things. It’s the speed of communication that’s enabling us to do things faster. In the old days, we might have been able to make a decision on a dime, and sometimes we would make a decision that wasn’t so informed.

We’re now able to tap a broader set of resources to make better decisions, but still at a very fast pace, and that part is exciting. I actually really enjoy the fact that we’re part of a bigger family and we have more minds that we can tap in terms of decision making, in terms of strategy, in terms of how to deploy resources. It’s actually been a chance for us to mature the company at a faster rate than we would have otherwise been able to on our own as an independent company.

No Data Found.

Content for this section will appear here once available