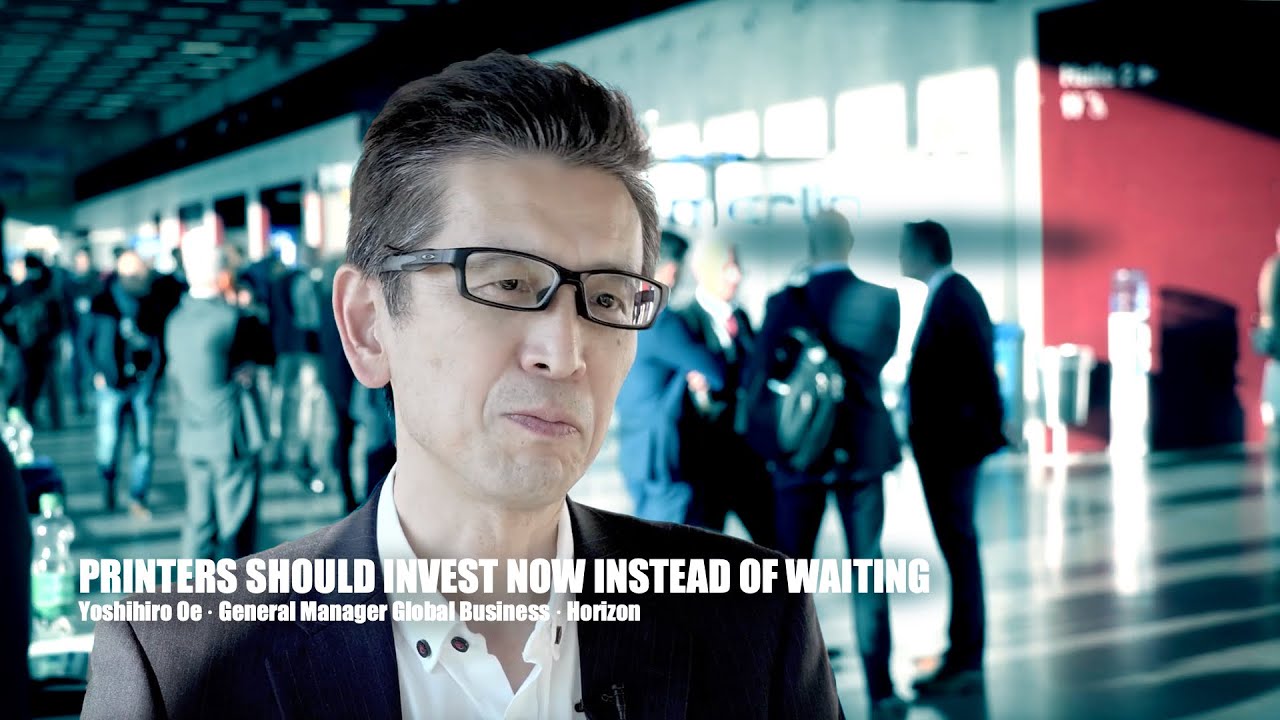

At the recent Hunkeler Innovationdays 2019, we got the chance to talk to General Manager Global Business Yoshihiro Oe from Horizon about global trends, the state of the industry from a Horizon perspective and how it is to work 32 years in the same company. This conversation was, and we hope you will enjoy watching it as much as we enjoyed doing it!

Yoshihirio Oe.

Hello.

You are the general manager of the world.

Yes.

For everything in the world.

Everything in the world, except the Japan.

At least when we talk of Horizon.

Yes that’s right.

So, we are here at the Hunkeler InnovationDays 2019 in the Lucerne and it’s really nice to see you have such a great booth this year, you have such great, nice equipment. I appreciate that you take the time to talk to us, even though we had a little technical problems here. Can you tell a little bit who you are?

Yes, I am General Manager of Horizon International global business. I am working for Horizon for 32 years. This is my first job and only job, so far.

See, when we look at each other, we can see that we come from different parts of the world right? That is good, because we can learn from each other. I was just wondering when you say 32 years in one workplace, that is not so common in Europe and in the US. Is that very common in Japan?

Yes, still Japan it’s very common to work in one company and stay in one company. That is very common. But nowadays the world in changing-

Also in Japan.

… also in Japan, there is more people, or younger generation is going to change job more often.

But when you started at Horizon, you didn’t start as a General Manager I guess?

No. I started as technical support for export division. That is my first job.

So, you are living proof that working hard pays off, right?

I think so. I think so, yes.

We spoke just a little bit before the camera was turned on, we spoke about both of us are working in a decreasing market unfortunately, right? Yeah, so what can we do to make it better?

Yes. This is a decreasing market. Unfortunately, it’s getting more and more difficult, but still print volume is certain amount, and this is not small. Digital printing is not large portion, yet.

When you mention digital printing in this, it’s because Horizon. Do you mainly make binding equipment, finishing equipment for digital, or you make for digital and offset?

Both digital and offset. We really don’t care how a customer prints. Yes, we just finish.

Correct me if I am wrong, but I used to work in a printing company. That was like a small digital printing company in Copenhagen and I remember Horizon in the first time, because Horizon, as you say, is both able to make offset, because large volume and big size sheets and small one. I think that’s one of your biggest advantages, since the market is moving from analog to digital, you have actually the products for supporting the customers, right?

From the beginning, our product is not for a long run. Our product has been always for short run business, even offset time, let’s say. Or not digital time. Our machine is originally short run. Digital is for short run. So, it matches perfectly. Let’s say we are lucky.

Even though the market is decreasing, since there’s this big shift from analog to digital, it seems that you are in a good hotspot for growth.

Yes, I strongly believe that is a position we should be because many of the bigger printing company, or the company who has a long run job, they are looking for a good short run solution at this moment, because the long ranks job ranks is much shorter than before.

Digital printers become faster and faster. They are very, very good quality when you look at the output of the print. I also think that customers today, they don’t really care so much if it is printed in offset or digital, but they expect the binding to be the same quality as in traditional. Is that a challenge from your perspective or?

You know that traditional offset printing, they are requiring a very high quality of binding from the beginning so for offset or for desktop, the finishing qualities are not big difference, and we are doing as we are. I hope the customer is accepting our products because of the high quality.

Yeah, I think they are very nice because I mean it’s also difficult to say that it’s not like, you know, if I talk about the Horizon products, I mean it’s difficult to say that something is not good or not bad because you have such a wide range of different types of products so you can do, you can do foldings, right? You can do stitching, you do perfect binding, you do hardcover, I mean you do all the things you are expecting from a digital finishing solution, right? Yeah.

If you look at more from a … If you talk a little bit about the business perspective, is the customers ready to adapt this thinking of small [inaudible 00:05:39] print runs, or are they still trying to force technology to be used … I mean let’s imagine that you have old binding equipment that is very good for long run, but you have paid for it, right? Now you have to invest in something new, but they say, “Oh, can we use the old one?”. Is that the game changer for the printing customer to actually get better equipment for short runs?

Yes, I think already some of the good thinking or advanced thinking customer is already changed some of the equipment or some of the way of thinking, or workflow. Let’s say they are the early adapter, but you have to be quick in this difficult market. If you wait for another year or two, you know everyone say, “Ah, let’s wait for Gruppe, there is something new coming”. I think they have to think now and act now.

Yeah.

Yes, and our equipment compared to traditional heavy duty, big equipment, our equipment is not so expensive investment, I believe.

Plus, I guess one of the advantages of equipment that can do specialized in the short run is that the setup time is much faster?

Yes, that is a key to our products. Yes, we don’t have a maybe super fast production running, but to eliminate or to reduce downtime is much more important for the customer, because the number of jobs nowadays is much, much more. Before, maybe they say “two or three jobs per day”, now they say, “1,000 jobs per day”.

Just imagine how many shifts you have to do right, performance and something like that.

Yeah, that’s right.

If we look a little bit ahead of the future, because unfortunately the forecast still believes that the volume will decrease and that will put an even higher demand on the printing companies. So, do Horizon as a company see the future? Can you be even more effective in the way you do new machines?

Of course our machines have to be fully automated. I think we need more automation to make the machine very, very easy to use for anyone because skilled operator is one of the biggest problem at this moment.

To find people who can operate this.

Yes, that’s right. And also, not only one single product, but as a product range or a product group, or system, it has to be workflow automated. I think this is-

So, that is where you combine it into like a JDF workflow or other workflows that automate the process from going from one equipment to another equipment, right?

Yeah, that’s right. We showed in this Hunkeler InnovationDays 2019, smart binding system, we called. This is a start with Hunkeler [inaudible 00:08:40] Cutter and then folded signature, stuck the signature, perfect bound book, and three knifed reaming. This is a combination of folding, stacking, binding, and three knifed reaming.

You know, when you mention this, it’s kind of fun, because isn’t that also what Hunkeler is doing, I mean are you competing with Hunkeler also?

No, not really. The Hunkeler doesn’t have really perfect binding or-

Okay, so you see that even though that you are in the same finishing with the same front ends, your binding equipment, or finishing equipment is more complimentary, for example to what Hunkeler is doing?

Yes, I think Hunkeler is focused on how to cut the raw sheet into a certain size and after that-

You take over.

We take care, yes.

Yeah, you take over, right. That’s cool. The future is of course very difficult to predict, but I was just wondering anyway because maybe it’s just because I don’t know it, but are we in the situation today where you can actually have digital print, and then have one off books with variable sizes. Is that like an option today?

Yes, some of our products is already capable to handle variable sized products.

That must be difficult to make.

Yes. But in the future there is more and more the size difference, or thickness difference, or format difference job is increasing so we have to handle in an automated way. So that is key for our success.

One of the things that I am personally interested in, is there is, if you talk about mega trends, you say there’s a lot of things go digital, everything that can go digital will go digital, but there’s also a mega trend saying the more a product is commoditized, the bigger the niche becomes. Do you also believe that there still will be a niche for like hand-binded products and for products that are more exclusive to the market? I mean do you deliver equipment for that kind of things as well, or are you more into the efficient workflows of binding? Or do you agree with me, is there a niche?

I agree, yes. Because, when I talk with printing company, they say they want to add value.

Isn’t that nice, because I guess every time you go into a printing company, you also talk about adding value, right?

Yes.

So, there’s different levels of adding value.

Yes, that’s right. So, some companies are very much dedicated in the hand crafts type of work. This is one segment exists, but many of the customer is doing, yes, add value by special finishing of special printing or coating, whatever. But this is, this requires a certain number of products and certain number of jobs to run. In this case, we are the one to support the customer.

Right. And will you work as, and this is the last question, we know we’re all busy, so was just wondering with your work as a GM for the world, as we spoke about right, what is your daily life like?

Daily life is always interesting.

I know that. I need to know a little bit more.

I learn and I challenge every day, which is interesting part of my life. As a General Manager of Horizon International, and I am now living in Hamburg, Germany, so I am very much close to the European customers. So, I really-

So, you have time to go and talk to customers as well?

I really want to visit customers as much as possible and to see and learn what is really needed for the customer and bring this information back to Japan.

So, that is also part of your work is to, understanding the market and if you see a challenge or if you have spot a chance, you get it back to you get it back to your R&D, basically.

Yes, that is a very important-

That must be a very funny job.

Yeah, this is an interesting, but difficult job. I try hard, yes.

So, when you go to a printing company, are they open in sharing the challenges with you?

Depends on the printer, but many are yes. They share the idea and they are looking for a collaboration pattern. We want to be a good, reliable partner for them. So that is our goal.

I know I said it was the last one, but I just have to ask, because you have recently, maybe a couple of years ago, you changed instead of having local distributors, at least in Scandinavia where I am from, in Germany you now sell directly to the market. Is that change due to the fact that you would like to get closer to your customers, or can you elaborate on this?

This is some mixture of reasons. Yes, we want to be closer to the market. Yes. But also, we have a very good dealer network. We very much rely on our loyalty dealers, our dealer is 35 years experience with the company.

They came at the same time as you did then?

Yes, that’s right.

Okay, well I guess that’s also part of the Japanese culture, that you are very loyal to each other, right?

Yes, that’s right.

Having that travel together with your customers, it must also give you a lot of encouragement, because I guess that if you bring a new product to the market, you know that you have friends and family that make sure that it is actually getting to the market?

Yes, that’s right. Yeah.

Is that a huge strength, even in the stressful world, as of today?

Yes. To communicating with the customer is interesting. But challenging. But yeah, we have to do, that’s my job. I will try my best.

I wish you the best. Oe, thank you very much, it was nice talking to you.

Thank you very much. Thank you.